Indent

What is an Indent?

An indent is a request sent to a transporter to provide a vehicle for moving goods. Once you’ve planned a load, you can raise an indent to ask a transporter to assign a vehicle.

An indent includes essential details like:

- Pickup location (where the goods are collected)

- Delivery location (where the goods are sent)

- Truck type (the kind of vehicle needed)

- Transporter name (the company providing the truck)

Example:

You’ve created a load and want Transporter A to send a truck. You raise an indent with the shipment details so they know when and where to send the vehicle.

How the Indent Module Works

The Indents module in TMS helps you create, track, and manage these vehicle requests.

With this module, you can:

- Create indents for one or more loads: After planning your shipment, you raise an indent by entering the required details.

- Send the indent to a contracted transporter. The indent is sent to the chosen transporter, requesting them to assign a vehicle.

- Track indent status: Monitor the status of your indent—whether it's been accepted, rejected, or is still pending.

- Update or cancel an indent if needed. This helps make sure that the right vehicle reaches the right place at the right time. It keeps your shipments organized and your communication with transporters clear.

From the Indents screen, you can:

- View and track the status of all active and completed indents.

- Filter and search for specific indents using multiple criteria.

- Take necessary actions, such as dispatching a truck or reporting an issue.

- Monitor SLA performance, such as delays and interruptions.

- Upload invoices and load details for efficient record-keeping.

Viewing Status

You can view the status of all the active and completed indents.

- In the Search bar, you can enter multiple Load IDs or any other IDs to directly find a specific indent.

Select any of the filters from the dropdown.

- Load ID: A unique identifier for each indent.

- Order ID: Associated order details, if applicable.

- Truck Number: The registration number of the truck assigned to the load.

- LR Number: The Lorry Receipt number provided for goods in transit.

- Invoice Number: The unique number assigned to the billing document for the shipment.

- From SLA Dropdown, you can filter from the following dropdown. It identifies indents facing delays such as:

- Acceptance Delay: Delays in accepting the indent.

- Placement Delay: Delays in assigning or placing the truck.

- Loading Delay: Delays in loading goods onto the truck.

- Unloading Delay: Delays in offloading goods at the destination.

- Transit Delay: Delays occurring during the transit phase of the shipment.

- In the Origin Center, enter the origin facility name.

- From Status dropdown, you can refine the list based on the indent's current status:

- Requested: Shipment request has been initiated.

- Accepted: Transporter has acknowledged the request

- Assigned: A truck has been allocated for the shipment.

- Marked In: The truck has arrived at its destination.

- Reported: The truck reported at the destination.

- In Transit: The shipment is currently en route.

- Marked Out: The shipment has been dispatched.

- Cancelled: The indent has been cancelled.

- From Service Type dropdown, filter by shipment type:

- LTL (Less Than Truckload)

- FTL (Full Truckload)

- From More Filters dropdown, you can select more filters:

Filter by additional criteria such as:

- Transporter Name/ID: Filter by the name or ID of the transporter.

- Destination: Filter based on the delivery destination.

- Manifestation Method (LTL): Select based on the method of shipment, such as Less Than Truckload (LTL).

- Truck Type: Filter by the type of truck assigned.

- Inspection: Filter based on inspection status or requirements.

- Tracking Consent: Filter by shipments with tracking consent enabled.

- Tracking Method: Filter by the method used for shipment tracking.

- Issues: Filter by shipments flagged with specific issues.

- Transit Delay Ageing: Filter based on the ageing of transit delays.

- POD Ageing: Filter based on the ageing of Proof of Delivery (POD).

Creating loads

From the Indent screen as well, you can create or upload loads and invoices.

- Load Upload: Bulk upload load information if you have multiple shipments to manage at once. See the bulk load upload documentation.

- + Load: Create a single load. See the single load creation documentation.

- Action Tip: Regularly review the status to ensure timely updates and to address any issues.

All the created or uploaded bulk load will be visible in Load module.

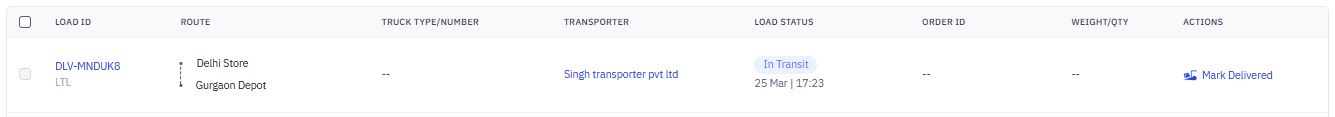

Viewing load listing

You can view and manage loads on the Indent module and perform required actions to dispatch the shipment.

When the load is allocated and contract is assigned to the transporter from the Load module, the transporter accepts and provide the required details. All these statues can be seen in Indent module.

1. You can track the load’s progress in the Expected tab to see a list of loads expected to pick materials from your facility.

Info:

- Warehouse Manager/Dock Manager can see list of loads expected to pick materials from their facility in Expected tab and their current status:

- Requested - Load is assigned to the transporter

- Accepted - Transporter has agreed to place the vehicle

- Assigned: Transporter has provided the vehicle details

2. After the transporter accepts, they will assign the vehicle and provide details. The status will change to Accepted.

3. Now the transporter will assign the vehicle and provide the details. The status will change to Assigned.

Dispatch, Truck Inspection, and Delivery

Manage the end-to-end process from vehicle arrival to dispatch. This section covers marking a vehicle as reported, inspecting trucks, and dispatching loads efficiently.

Report Vehicle as Mark Reported

The Mark Reported feature allows you to confirm a vehicle's arrival at the facility.

1. If GPS is enabled, the system auto-detects the location and marks it as Arrived. If GPS is unavailable or inaccurate, you can manually mark the vehicle as Mark Reported.

- The vehicle will appear in the Arrived tab.

- Dock Manager can cross-check the truck and driver details, modify if-necessary.

- Dock Manager provides the reported on time and submit to mark the vehicle reported.

2. Click Inspect Truck to inspect the vehicle.

3. You can check the vehicle details and mark the inspection as either Success or Failed.

- The Dock Manager can check vehicle details fetched from the Govt portal.

- The Dock Manager can physically inspect the vehicle.

- Depending upon vehicle state, Dock Manager can either mark Inspection Success or Failed.

4. After you inspect the truck details, you get the confirmation message of Inspection completed.

Dispatch shipment

5. Click on the Load ID to view the details page.

6. You can view the load details, including the route it took and all the stages of its journey.

7. Once the truck leaves the facility, the system will automatically dispatch the vehicle or you can manually dispatch it by clicking the Dispatch button and confirming the dispatch time.

4. Once dispatched, the load status will be changed to InTransit status.

Mark Delivered

8. After dispatch, you can click Mark Delivered.

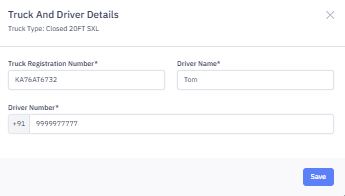

Edit Truck and Driver details

You can modify truck and driver details as needed, even when the vehicle is in transit. This allows for quick updates in case of any unexpected issues, such as a vehicle breakdown or a driver unavailability.

To edit truck and driver details:

1. In the Allocated tab, select the transporter whose truck or driver details you want to edit under the Transporter and Contact ID column.

2. On the details page, click pencil icon.

3. On the edit page, modify the necessary details, such as:

- Truck Details – Update or replace the truck in case of a breakdown.

- Driver Details – Assign a new driver if the existing driver is unavailable.

4. Click Save to save the changes.

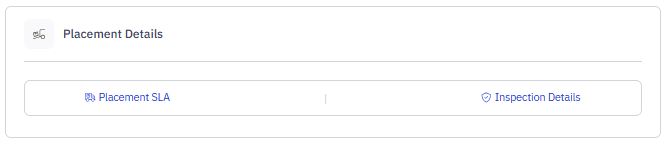

Edit placement details

1. On the details screen, scroll a bit, you will see Placement details section.

2. Click Placement SLA and edit the acceptance placement TAT details.

3. Click Save.

Managing LR (Lorry Receipts)

You can manage LR, lorry receipts- add, edit, and delete LR.

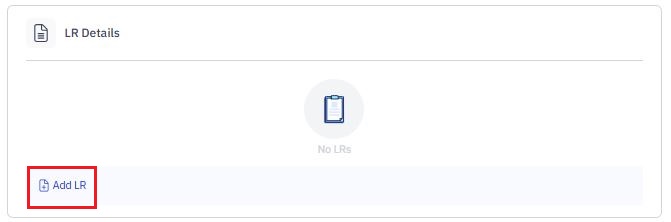

Adding LR

To add LR, follow the below steps:

1. Select load ID for which you wish to add LR. Its details page will be open.

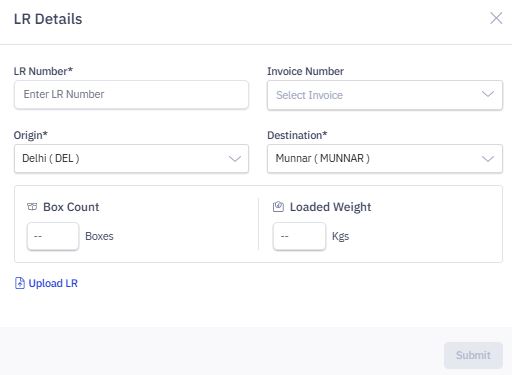

2. On this page, click Add LR.

3. Enter the required details and click Submit.

4. After submitting the details, the LR would be added.

Info: You can add more than one LRs.

Editing LR

1. To edit or modify the LR, you can simply click on added LRs and edit.

2. Once you are finish editing, click Submit.

Deleting LR

- To delete the LR, click on delete icon to delete the LR.

Managing POD

You can add, edit, and delete the POD.

Adding POD

- You can add POD from the LR screen, click POD and upload proof of documents.

Editing POD

1. To edit or modify the POD, you can simply click on added POD and edit.

2. Once you are finish editing, click Submit.

Deleting POD

- To delete the POD, click on delete icon to delete the POD.

Managing Materials

1. You can upload materials or upload invoices from the Load detail page.

2. You can upload LR details. Alternatively, the transporter can also upload LR details.

Managing Invoices

Add or upload invoices related to your shipments. This ensures all necessary financial records are tied to the corresponding indents. You can add, upload, edit, and delete invoices.

This ensures all necessary financial records are tied to the corresponding indents. To add, upload, edit, and delete invoices, refer to the Managing Invoices section in Load documentation.

Uploading Invoices

From the Loads screen, you can upload invoices. To do so, follow these steps:

- Click

.

- Click Download Template to understand how you will fill the invoice information.

- Fill in the required information as per the template format.

- Save the file in CSV.

- Upload the file.

- Click Process.

7. The invoice will be uploaded and you can view the uploaded invoice in the Tasks module.